Manuscript available in Journal of Stored Product Research.

This project ran as part of my PhD. I was lead on this work, and completed the majority of it. Helene Larsson Jönsson, my supervisor, was along for the ride, keeping me on the road, and is co-author.

ABSTRACT FROM FINAL REPORT

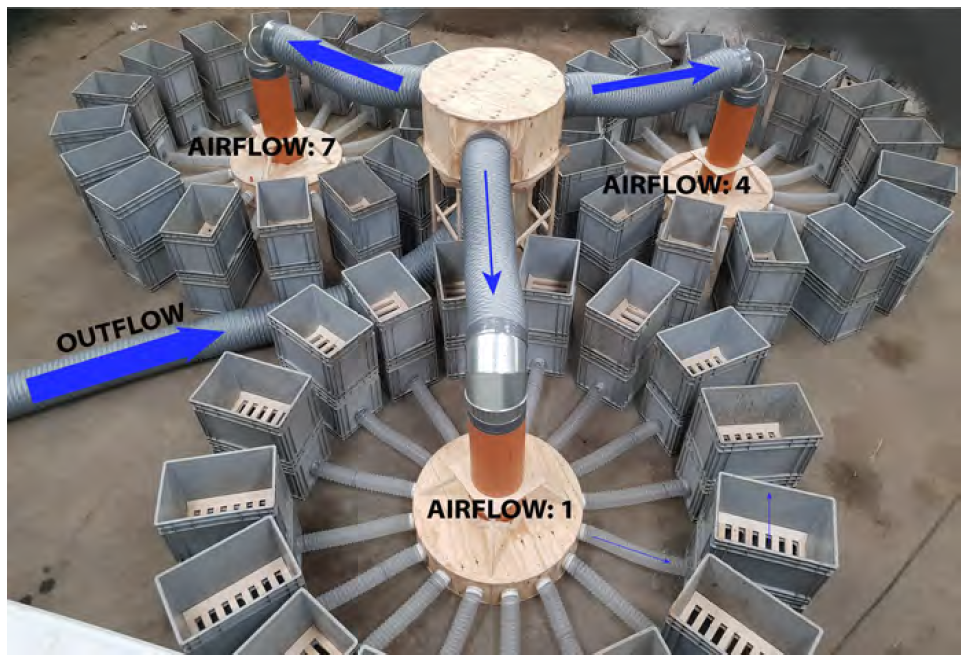

Active ventilation of stored sugar beet roots is used to control system temperature and slow the loss of quality that occurs with plant respiration and the growth of pathogens. Ventilation can at the same time increase rates of dehydration and dehydration related stresses of the stored sugar beet roots. Recent research into the use of forced ventilation to modify temperature in in-field sugar beet root stores has suggested that a controlled dehydration of roots could lead to improvements in quality. This work aimed to investigate the impacts to sugar beet root quality from short-term, high volume airflow during post-harvest storage. A modified environment experimental setup was developed. The experiment tested four airflow rates over three levels of ventilation duration, with the longest duration being seven days. Air temperature and relative humidity was constant within each seven day run, but varied between runs. Results showed that a mean weight loss of 11.7% with a corresponding increase in sucrose content of 13.2% was achieved at the highest airflow rate and ventilation duration. These changes in quality were a result of the transfer of water from the sugar beet roots. No reduction in total sucrose or other quality parameters was observed. The dependence of the rate of water transfer from the roots on airflow rate was quantified as the convective mass transfer coefficient. Estimates are given and cross-validated using dimensional analysis.

RATIONALE FROM AN APPLIED SCIENCE VIEWPOINT

Increase understanding of the impact of the movement of air, and of temperature and humidity on the movement of water and on quality parameters in sugar beet post-harvest storage systems […]. This will give insight into how airflow can be managed to improve quality parameters in commercial operations. It will also support the further development of models of sugar beet post-harvest storage systems.

English, 2023, PhD Thesis.

Regarding quality, the aim was specifically to investigate whether a short and sharp ventilation period could be used to force water out of the system and thus increase sugar content and reduce dirt-tare, while also not have negative impacts on total sugars and all other quality parameters.

Regarding movement of water as a function of airflow, one of the major achievements was to quantify mass flux (ie the rate at which water leaves roots, per surface area and time), and the impact of airflow on this mass flux (via the parameter known as the Convective mass transfer coefficient).

DESIGN

For now, see the sections 1.1.2, 1.2.1, 1.2.4 and 1.2.5 of my PhD thesis.

KEY NOVEL FINDING FROM AN APPLIED SCIENCE VIEWPOINT

From article:

This experiment showed that a short and intense ventilation of sugar beet roots during post-harvest storage has the potential to benefit the industry, in that it can result in a much reduced weight of the bulk of raw material while not having negative impacts on quality. The reduction in weight results from a reduction in water content. This reduction in weight could have many benefits. In payment systems that incentivise higher sucrose content and lower dirt-tare, sugar beet growers could see increased gross incomes if ventilation occurs prior to delivery. Further benefits in the form of reduction in transport costs and environmental impact would also follow.

English & Larsson Jönsson, 2023